Many people become confused when doing online research for air scrubbers as negative air machines appear alongside them in search engine results. This can be misleading to those who aren’t familiar with the differences between the two, as often the two terms are used interchangeably.

With the proper setup, portable air scrubbers are designed to double as negative air machines.

In this guide, we cover everything you need to know about air scrubbers and negative air machines.

Table of Contents

Air Scrubbers

An air scrubber is a standalone machine that traps airborne particles and helps improve air quality indoors. They are used in a variety of environments and have many uses including disaster restoration, mold removal, and dust removal during construction and renovation. Check out our ultimate guide on air scrubbers for more details.

Negative Air Machines

Negative air machines are used to create air pressure differentials between two spaces. This means they can be used to create a space where the air pressure is lower than the surrounding area or they can be used to create a space where the air pressure is higher than the surrounding area. Each set up has its own use.

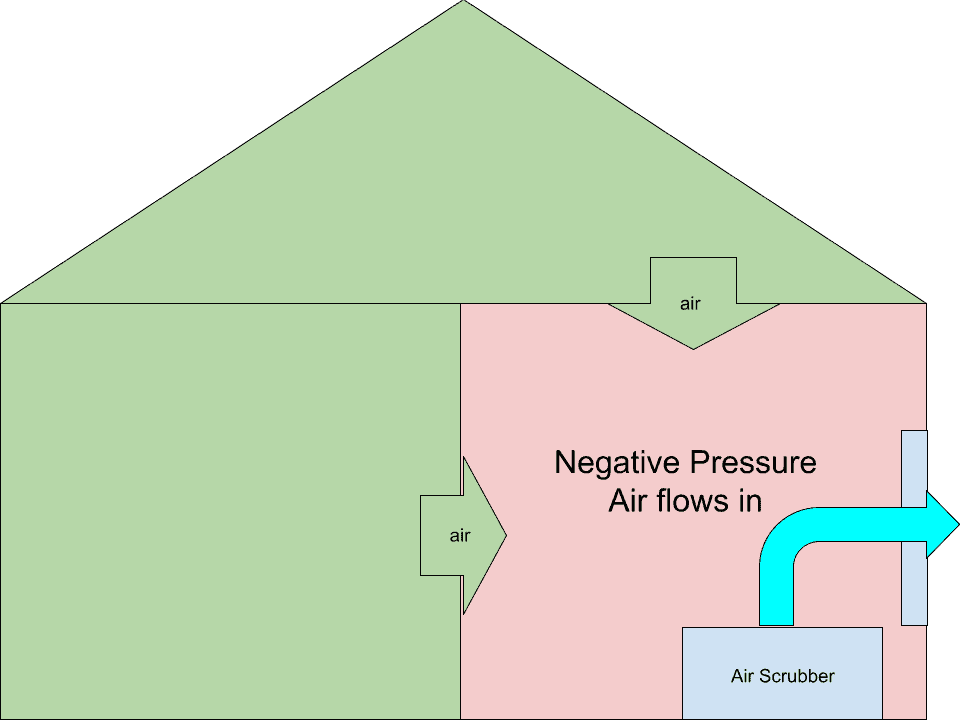

When a negative air machine is used to create an area that has a lower air pressure than the surrounding space this is called a negative air pressure environment.

Because air flows from a higher pressure environment into a lower pressure environment, creating a negative air pressure environment essentially traps any particulates inside the negative air pressure environment from escaping.

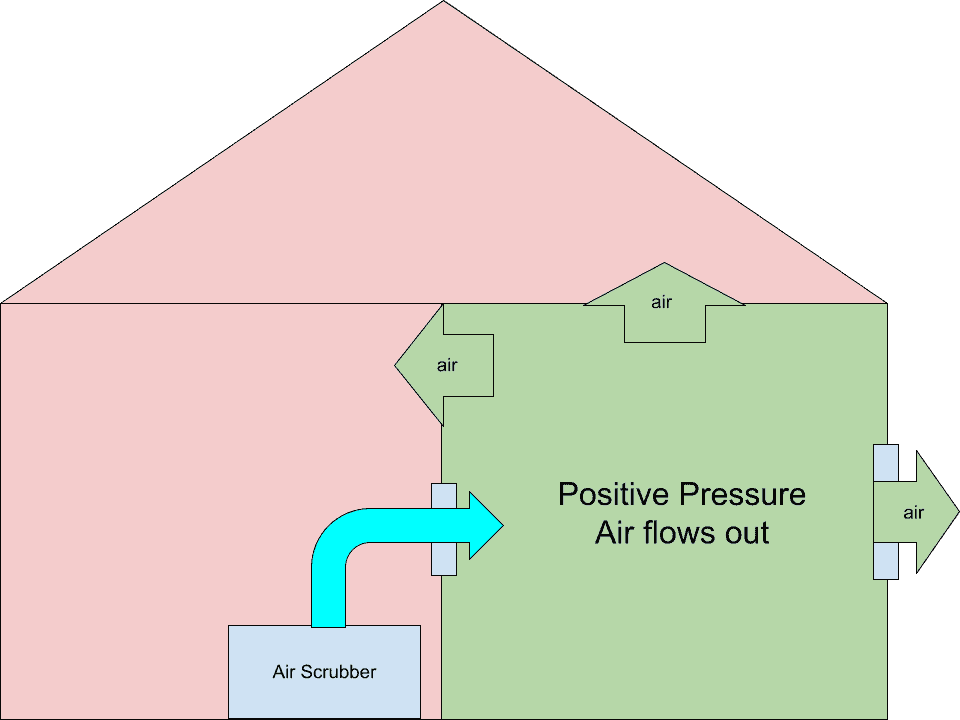

When a negative air machine is used to create an area that has a higher air pressure than the surrounding space this is called a positive air pressure environment.This has the benefit of preventing unwanted particulates in the air from entering the high pressure space.

While air scrubbers focus on air filtration, dedicated industrial negative air machines focus more on throughput. The CFM (the amount of air that is moved) of dedicated negative air machines is much higher than what you will find on your standard commercial air scrubber. While the focus is on throughput, negative air machines also include filters, although some only have pre filters which aren’t as effective at air filtration as the HEPA filters you usually find in air scrubbers.

But again, for most commercial use cases (remodeling, renovation, construction, etc…) an air scrubber will work just fine as a negative air machine.

Negative Air Pressure Environment

A negative air pressure environment is created when the air pressure inside a room is lower than the pressure outside it. This ensures that contaminated air from the lower pressure room does not spread.

Air that is filtered out of a negative pressure environment is usually passed through a high-efficiency particulate air (HEPA) filter that removes bacteria, dust, and other impurities.

Negative air pressure environments are commonly set up for construction and remodeling jobs to prevent dust and other contaminants from leaking out of the work space.

How To Set Up A Negative Air Pressure Environment

When setting up a negative air pressure environment, the isolated room must have lower air pressure. To create a negative air pressure environment you should follow these guidelines:

1. Create a containment area for the room. All gaps should be properly sealed, including doors, windows, and ceilings. Leave a small opening unsealed for proper ventilation.

2. The air scrubber must be placed in the isolated room with the outlet properly ducted to expel the filtered air out of the room.

3. The air exiting the room must run 10% to 15% higher than the air entering the room

4. Pressure should be monitored, Pressure differential should be less than -2.5 Pa

5. Ensure there are greater than 12 Air Changes per Hour (ACH)

Check out this short video showing a negative pressure set up:

Youtube video showing negative air pressure setup (Start at 0:52)

Positive Air Pressure Environment

A positive air pressure environment is created when a room has higher air pressure than outside it, so viruses, bacteria, and contaminants can be kept out.

Positive air pressure environments are used in hospitals to protect patients in operating theaters to ensure that proper air quality is maintained. It is essential to reduce the risk of contamination, disease, and other conditions associated with a compromised immune system.

Positive air pressure environments are also used in the microelectronics industry, where the integrity of microchips and circuit boards must be maintained during the manufacturing process.

How To Set Up A Positive Air Pressure Environment

When setting up a positive air pressure environment, the isolated room must have higher air pressure. To create a positive air pressure environment you should follow these guidelines:

1. A containment area should be set up with all gaps properly sealed, including doors, windows, and ceilings. Leave a small area unsealed for proper ventilation.

2. The air scrubber must be placed outside the isolated room with the outlet properly ducted to exhaust the filtered air into the containment area.

3. The air entering the room must run 10% to 15% higher than the air exiting

4. Pressure should be monitored, the pressure differential must be over 8 Pa

5. Ensure that there are greater than 12 Air Changes per Hour (ACH)

How To Create A Containment Area and Monitor Pressure

To create the containment area you can use plastic sheeting or zipwall. Just remember to leave a small opening so that some air can still enter or exit the room.

If you want to accurately measure air pressure you can use a manometer, but if your use case doesn’t require strict adherence to the guidelines, you can use a simple smoke pen or even incense to make sure the isolated room has negative pressure.

The smoke pen, as the name implies, releases a small amount of smoke when activated. To check for positive pressure, place the smoke pen near the unsealed opening of the isolated room. If positive pressure has been achieved, the smoke will flow out of the opening instead of back into the room.

To check for negative pressure, place the smoke pen near the unsealed opening of the containment area. If negative pressure has been achieved, the smoke will not flow out of the opening and instead it will flow back into the containment area.

Finally, if you’re ready to set up a negative or positive air pressure space, but not sure which air scrubber you should use for the job, check out our list of the best air scrubbers.

I do the research so you don't have to.