Table of Contents

What Is An Air Scrubber?

Commercial air scrubbers, sometimes referred to as portable air scrubbers, air wash units or commercial air purifiers, are standalone machines that remove unwanted airborne particulates from indoor environments through the process of filtration.

They are effective at removing a variety of contaminants from the air including bacteria, gasses, molds, chemicals, odors, smoke and volatile organic compounds, or VOCs.

Air scrubbers are often called portable air scrubbers (PAS) as most units are made to be moved around on job sites. Most can be moved by a single person but may require a second to lift them off the ground.

Types of Air Scrubbers

Integrated Air Scrubbers

Although integrated air scrubbers are also referred to as ‘air scrubbers’, they are only air scrubbers in name. These devices are not suitable for commercial use.

Integrated air scrubbers do the same thing an air scrubber is designed for — remove air pollutants and particles from the air and surrounding surfaces. However, they are designed to be connected to an existing HVAC system, check the FAQ for more details.

Portable Air Scrubbers

How Air Scrubbers Work

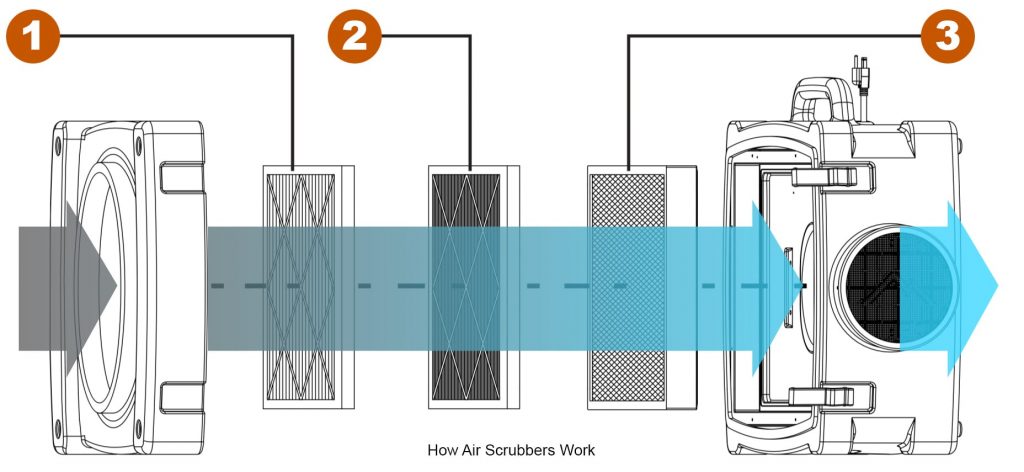

Air scrubbers work by passing air through a series of filters to remove whatever pollutants the filters can catch. Most all units have multiple filters, each trapping a different size of particulate.

Air is introduced then passes through three levels of filtration before being exhausted.

- Dirty air is drawn into the air scrubber at one end

- As air is sucked through the unit, filters remove airborne pollutants

- Clean air is exhausted out the other end of the air scrubber

Once the air has passed through the filters it is either removed from the environment entirely (such as exhausting it outdoors) or is exhausted into the same room.

Parts of An Air Scrubber

A portable air scrubber is a stand-alone unit with several parts working in concert to eliminate the particulates in a space. While an integrated air scrubber relies on the HVAC system to function, a portable unit works independently using the following parts:

- The Inlet: The unit takes in the air for purification using the inlet ports. Inlet size must be considered when buying ducting.

- The Outlet: Once the air filtration has occurred within the system, the filtered air is released through the outlet port. Outlet size must be considered when buying ducting.

- Filters: Many air scrubbers include 3-stage filtration, which is a fancy way of saying the air scrubber passes the air through 3 different filters. Ideally the filters have different uses and each specializes in removing certain particulates from the air.

- The Control Panel: All portable air scrubbers have a control panel used to operate them. Depending on the brand, the available features on the control panel will differ. Below are some features that may be available on an air scrubber unit:

- Power indicator

- Filter change indicator

- Variable-speed fan control

- Dual plug GFCI-protected receptacles

- 12-amp circuit breaker

- Toggle switch

Types of Filters

Like various other filtration systems, the air scrubber uses filters to remove all of the impurities as the air is circulating through the system. The scrubber collects the contaminated air and releases purified air with the help of the filters. So long as the filters are in place and are in great condition, the unit will provide clean air. Each filter is used for different purposes:

- Pre-filters: This is usually the first stage of the filtration process. The filter collects much larger particles from the air before reaching the main filter. It is designed to remove insects, pollen, dust, hair, etc. After capturing the much larger particles, the air proceeds through the other filters in the unit for further purification. The major purpose of the pre-filter is to help enhance airflow, increase filtration efficiency, and extend the life cycle of the more specialized filters. Pre-filters are generally changed the most frequently.

- Carbon filters: These filters are most effective against volatile organic compounds (VOCs) including soot and smoke, food odors, sewer odors, fumes from paint and paint thinners, and other compounds. The filter removes contaminants through adsorption — attracting contaminants to the surface of the filter. Carbon filters are usually an optional level of filtration when available. Carbon filters typically remove particles in the 0.5 to 50 micrometer range.

- HEPA filters: Most air scrubbers and purifiers leverage HEPA (high-efficiency particulate air) filters to capture small particles such as mold, bacteria, dust, asbestos, lead, and many other airborne contaminants as tiny as 0.3 microns. The filter works by trapping the pollutants and can capture up to 99.5% of particulate pollutants. They are very effective at removing fine particulate matter from the air.

Pollutants Air Scrubbers Remove

Many small, even imperceptibly sized pollutants can be removed including:

- Airborne toxins

- Bacteria

- Chemical odors

- Dust and dust mites

- Fungi

- Mold spores

- Pet dander and hair

- Plant spores

- Tobacco smoke smell

- Wood smoke smell

- Viruses

- Volatile Organic Compounds (VOCs)

Air Scrubbers VS Covid 19

When used with a HEPA filter, air scrubbers can reduce the amount of SARS-CoV-2 (Covid) particles in the air.

But keep in mind, an air scrubber alone is not enough to protect one from the coronavirus.

Air Scrubbers VS Mold

Air Scrubber Effects on Indoor Air Quality

- Improves Respiratory Health: In cases of asthma sufferers, air scrubbers are very effective units that help improve air quality. This, in turn, helps improve quality of life and ensure that they are not affected by any unfiltered air.

- Helps prevent allergies: The air scrubber filters particulates that are the source of many allergies including dust, pollen, and other pollutants in the atmosphere.

- Has a positive impact on vascular health: From low-income countries to high-income countries, long-term exposure to pollution has a major impact on our cardiovascular system. However, an air scrubber unit reduces the amount of airborne particulate matter, resulting in improved blood vessel health and reducing the risk of cardiovascular disease.

What Commercial Air Scrubbers Are Used For

Disaster Restoration and Mold Removal

Construction

Hospitals

Remodeling

Used in Businesses At High Risk For Low Air Quality

Frequently Asked Questions (FAQ)

Do Air Scrubbers Produce Ozone?

In short, no, portable air scrubbers do not produce ozone. Check out our post on this topic for more details.

How Many Air Scrubbers Do I Need?

The number of air scrubbers you need depends on the size of the space, the number of air changes per hour (ACH) you want, and the strength of your air scrubber. Check out our calculator page to determine how many air scrubbers you need.

How Does An Air Scrubber Compare To An Air Purifier?

Air scrubbers are generally used in commercial situations like removing mold from a home or business, or to deal with smoke and water damage following a fire.

Since air scrubbers are used in such environments, they don’t need to be, and in general aren’t, quiet or very aesthetically pleasing. They’re also built with the rigors of constant operation in mind, usually housed in a tough plastic case and often one with wheels.

Air scrubbers and air purifiers do share a lot in common. Both are used to purify air. However air scrubbers typically have higher CFMs and more layers of filtration.

Air purifiers are meant to be used inside a home or business when it is occupied. They are engineered to run quietly and to fit in to their surroundings.

How Does An Air Scrubber Relate To A Negative Air Machine?

The term negative air machine is often incorrectly used interchangeably with air scrubber. While they share many similarities, they are not the same. All commercial air scrubbers are negative air machines as they both operate on the principle of negative air pressure. Both also employ filters to remove impurities in the air.

As far as differences go, negative air machines are generally larger and not as feature rich. Their size and weight makes them suitable for very large jobs where the unit is intended to be stationary most of the time. As moving the unit can require several workers, their often employed on jobs where there is a larger staff present.

Air scrubbers, in contrast, are usually smaller in scale and specifically designed with portability in mind. As mentioned above they are often referred to as portable air scrubbers (PAS) as this portability is all but a given in their design. Portable air scrubbers are desirable, especially for smaller crews, as they can be maneuvered by a single person, including moving them up or down stairs, and often even lifting them into a vehicle.

For more information, including how to set up a negative air pressure environment check out our post on air scrubbers vs negative air machines.

Is The Air Scrubber Plus or Air Scrubber By Aerus The Same As A Commerical Air Scrubber?

These are sometimes referred to as integrated air scrubbers. Both of these products, the Air Scrubber Plus and Air Scrubber by Aerus, refer to a residential product as opposed to a commercial air scrubber. The product is integrated into a homes HVAC system by placing it in the ductwork. The product differentiated itself from the approach taken by high grade residential MERV 13 air filters with what they called ActivePure technology.

To quote Aerus, their product could “go beyond traditional air purification systems by not only eliminating stale odors and reducing dust, but actually eliminating harmful contaminants* in the air and on the surfaces of your home.”

Regardless, while these products leverage the Air Scrubber name, they are not commercial solutions or of use to a water damage, mold remediation or restoration professional.

Is It Better To Rent Or Buy An Air Scrubber?

It really comes down to need. If an air scrubber is only going to be used for a few days or a week, then never again, renting likely makes sense. If you are starting a renovation, water or smoke damage, or mold remediation business you want to choose from the best air scrubbers on the market. Making an investment in professional grade equipment will ensure your success and will be far cheaper over time.

How Much Do Air Scrubbers Cost?

You can expect to pay $450 to $750 for a professional-grade portable air scrubber. Some models with greater levels of filtration, higher airflow and other options can cost up to $1,000, however. And, for specialized scrubbers, such as for use in a medical environment or for lead abatement work, costs start at $1,000 and go up from there.

I do the research so you don't have to.